The ThyssenKrupp Quarter

Essen / Germany / 2006

35

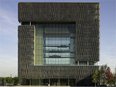

The competition brief for the ThyssenKrupp Quarter called for a “consistent” self-contained building ensemble. Expectations were not for a solitary symbolic high-rise but for an expansive and flexible cluster of equal-ranking buildings capable of responding to change processes within the Group. Based on these specifications, the joint design submitted by the TKQ architect consortium JSWD Architekten and Chaix & Morel et Associés was selected as the winner ahead of 105 other entries. It was just a small but logical step from the idea of a “consistent ensemble” to the design of a campus architecture.

The ThyssenKrupp Quarter consists of a cluster of individual buildings embedded in a green, tree-studded carpet. Linked by short paths and small squares, the buildings line a central ordering axis comprising a large water basin and the “Avenue of the Worlds”. In addition to this general development plan, the TKQ architect consortium JSWD Architekten and Chaix & Morel paid particular attention to the architectural consistency of the individual buildings. The aim was to create a quarter with a compact and homogeneous architectural appearance conveying a strong sense of unity. The campus is dominated by intricate facade structures of metal and glass. The floor-to-ceiling glazing reinforces the impression of openness and transparency.

The “shell – core” principle

The overriding design motif applied to all the new buildings on the campus is the “shell – core” principle. All buildings in the quarter are composed of L-shaped elements enclosing a shared central space. This gives a clear alignment not only to the headquarters (Q1) but also the forum building (Q2) and the neighboring office buildings Q5 and Q7. There are two types of facade: One faces the central space, the other faces the exterior and is therefore responsible for the impact the buildings create in the surrounding area.

These exterior facades vary the appearance of the “basic shell”. In building Q1, the “basic shell” is dominated by the horizontal slats of the external sunshade system. In the forum, too, the architectural motif is incorporated in the external sunshade system made of perforated stainless steel sheets. In Q5 and Q7 the “basic shell” idea is conveyed as a playful structure of horizontal and vertical stainless steel slats.

The atriums and inside courtyards are based on a different design idea: Large, smooth color-coated sheets are used to finish the facades. Windows to allow light into offices facing the courtyards are cut out of the sheets in the form of large elongated openings. Each facade type has its own individual appeal, but it is the interplay between shell and core that creates the overall effect. The consistent application of this principle to all buildings on the campus was key to the homogeneous architectural impression now created by the new ThyssenKrupp Quarter.

Q1

The building Q1 in the context of the ensemble, is the heart of the new ThyssenKrupp Quarter. More than 500 people will work in the cube-shaped building. At a height of 50 meters it towers over all the other buildings on the campus without being over-dominant.

And it is not its height but its striking, expressive shape that gives the building its elevated status. The geometric interlinking of different volumes around a shared central space not only creates a visually exciting exterior, but also provides for interesting room sequences inside the building. At the center is the glass-roofed atrium. It extends over ten stories and comprises a number of mezzanines and platforms. The north and south faces, each overlooking the water axis, feature 28.1 by 25.6 meter panoramic windows. They each comprise 96 separate glass panes held together by a thin, barely visible cable structure so that the windows appear to be made from a single gigantic sheet of glass.

Alongside the overall architectural impact of the building and its interior qualities, the use of material and design in its facades plays a key role. The sunshade system illustrates how the architecture of the new campus is united with the product world of ThyssenKrupp. For the construction elements of the sunshade system developed by the architects and planning partners, ThyssenKrupp stainless steel products were used over a total facade area of 8,000 square meters. As the building’s owner, ThyssenKrupp provided full support in the search for technically innovative solutions and efforts to meet optimum building standards.

Q2

The building Q2 is the place for meetings, exchanges and project work. International project teams work in the Q2 forum, and this is also where the Group receives its guests. The main conference and events hall can seat up to 1,000 people. The building also houses the staff canteen and guest restaurant. And last but not least, the Q2 forum is the underground logistics hub for the entire ThyssenKrupp Quarter.

The Q2 forum’s particular flair lies in its unconventional room sequences: It is comprised of alternating single-story and two-story areas. The three main levels are joined together in several places by shared atriums of different heights. The experience of space and enhanced functionality give the Q2 forum a particular appeal, making it a key focus of attention on the campus.

Buildings Q5 and Q7

The sculpting of the building form is also a central design element in buildings Q5 and Q7. The two L-shaped elements together forming one building are given spatial definition by recesses in the ground floor. Deep incisions in the cube-shaped upper stories in the form of recessed balconies and conservatories give the five and seven story buildings unexpected accents compared with conventional office buildings. Some 220 employees will work in Q5 and around 300 in Q7. The two L-shaped sections are joined at each end by bridges. These, too, create deep recesses in the building volume and make for attractive proportions.

ENVELOPE

All of the building façades on the campus have been designed according to the “Shell and Core” principle, which is expressed in two façade types: while the “shell” defines the façades of the building volumes towards the exterior and the open spaces, the “core” is oriented towards the interior courtyards and atriums. The objective of these design leitmotifs is to underline cohesion between the buildings and thus the architectural homogeneity of this campus beyond the shared formal language of its building volumes.

The “shell” type consists of a thermally effective floor-to-ceiling metal-glass façade in post, beam, or elemental building structure. A metallic shell has been placed in front of these at various distances to bear sun-shading systems, which differ from building to building. The material “stainless steel” defines the outer appearances of all of the building envelopes, to express a uniform corporate architecture. All of the façades are characterized by a dominantly vertical structure, so that the horizontal lines of the story levels fade into the background, making the façades look homogenous in appearance over the whole height of each building; these multi-layered façade surfaces thus make the campus buildings look like abstract metal volumes. The individual buildings’ partly recessed glazed ground floor façades and the glazed floor-to-ceiling building joints represent a further connecting element within the campus architecture.

The above-mentioned metallic-rough “shells,” the reliefs of which differ in depth, stand in contrast to the colored, smooth “core façades” of the campus buildings. While the exterior-oriented façades vary, the “core” façades are designed identically. The homogenous color and surface design of the opaque “core façades” unifies the whole campus appearance, reinforcing the relationships between its buildings. The “core façades” have been clad from floor to ceiling in sheet metal panels painted using coil coating, and developed and produced especially for the

Q1 An innovative, highly efficient sun shading system was developed for large parts of the Q1 façade based on the design principles described above. Apart from the panorama window, this sun shading system defines the character of the Q1 building.

Its sun shading elements, which look like metal feathers from afar, consist of approximately 3,150 routered vertical stalks; stainless steel double axes, onto which approximately 400,000 horizontal stainless steel louvers have been screwed. These rotatable and intertwineable elements represent an optimized system that combines the advantages of horizontal louvers (allowing light to enter) with those of vertical rotatable louvers (unrestricted views). The over 1,280 lineal motor-driven, centrally-controlled individual elements can perform the following basic operations: closed (parallel to the thermal glazed envelope),

following the position of the sun (variable, perpendicular to the angle of entry of the sun) open (the horizontal louvers intertwine over a double-axis, perpendicular to the thermal glazed envelope).

Their differentiation into trapezoidal, triangular, and rectangular individual elements gives the façade a structure on which the changing play of reflecting sunlight throughout the day creates an almost artificial-looking orchestration of the architecture. The sun shading system is also part of the building’s energy concept. It protects from overheating and when it is closed, it directs natural light into the interior spaces. Views from the windows to the open spaces are still guaranteed due to the rotational function of the system. This system has made it possible to transfer the technical and functional necessities of a modern office working world, from a sustainability and energy efficiency point of view, into well-designed architecture.

Q2 The exterior sun-shading also defines the overall appearance of the Forum within the context of a superordinate campus architecture. Its architecture is defined by vertical rotating elements that consist of two components: rotatable axes made of stainless steel pipes and the perforated two-millimeter-thick panels made of stainless steel, which cantilever from the axes. As in the Q1, the system consists of individual elements of varying dimension. Motorized, centrally controlled louvers follow the sun at right angles, providing efficient sun-shading to the largely north-south oriented façade surfaces. The louvers remain relatively transparent even when closed due to the approximately twenty-five per cent perforation of their panels and the very small dimensions of the openings.

The thermal exterior skin, positioned thirty-five centimeters behind those louvers, consists of a floor-to-ceiling post and beam structure and double insulation glass.

The opaque façade areas of the Q2 have been clad in vertical, bevel-edged, stainless steel panels, which express a continuation of the rhythm of the rotatable louvers in dimension. When they are closed, the façade and building volume become homogenous and abstract in appearance. When the rotatable louvers are open, the building volumes are revealed to be a composition of two intertwined L-shaped building components. The floor-to-ceiling glazed ground floor façade does not have any exterior sun-shading, making the building appear to float above the central reflecting pool. The façade system consists of a post and beam structure with vertical posts with open steel profiles, manufactured by ThyssenKrupp.

Q5/Q7 The structure-endowing shell of the Q5/Q7 building is defined by a grid of stainless steel elements positioned in front of a thermal envelope. Its vertical stainless steel elements become more dense around the floor-to-ceiling casement windows, providing natural ventilation to the offices and fall protection. The louver structure in front consists of individual rectangular stainless steel hollow profiles (w = 20 mm / t = 180 mm). The roll formed profiles, made of one millimeter-thick stainless steel, are connected at their crossing points using adaptors.

A motorized sun-shading system of Venetian louvers is positioned at the front of the ceiling behind the stainless steel structure. The vertical stainless steel elements, which dominate the appearance of the façade, and the fine pattern of the horizontal sun-shading louvers, create an orthogonal web, which gives the Q5 and Q7 buildings an abstract, large-surface appearance. Punctual floor-to-ceiling incisions into the Q5/Q7 building volumes structure the façade. This formal gesture stands in dialogue with the plastic incisions into the volumes of the buildings Q1 and Q2, which accommodate special areas such as loggias and special meeting rooms.

35 users love this project

Enlarge image

The competition brief for the ThyssenKrupp Quarter called for a “consistent” self-contained building ensemble. Expectations were not for a solitary symbolic high-rise but for an expansive and flexible cluster of equal-ranking buildings capable of responding to change processes within the Group. Based on these specifications, the joint design submitted by the TKQ architect consortium JSWD Architekten and Chaix & Morel et Associés was selected as the winner ahead of 105 other entries. It was just...

- Year 2006

- Main structure Reinforced concrete

- Client THYSSENKRUPP REAL ESTATE GMBH

- Cost 300 million

- Status Completed works

- Type Office Buildings / Showrooms/Shops

comment