DESIGN_ In order to manufacture final products, machines are becoming less and less dependent on humans. As a result, the typical human touch is disappearing in almost all products we use and see in our day-to-day life. The Pressed project of Studio Floris Wubben has the capacity to show properties of materials in an unusual and triggering way.

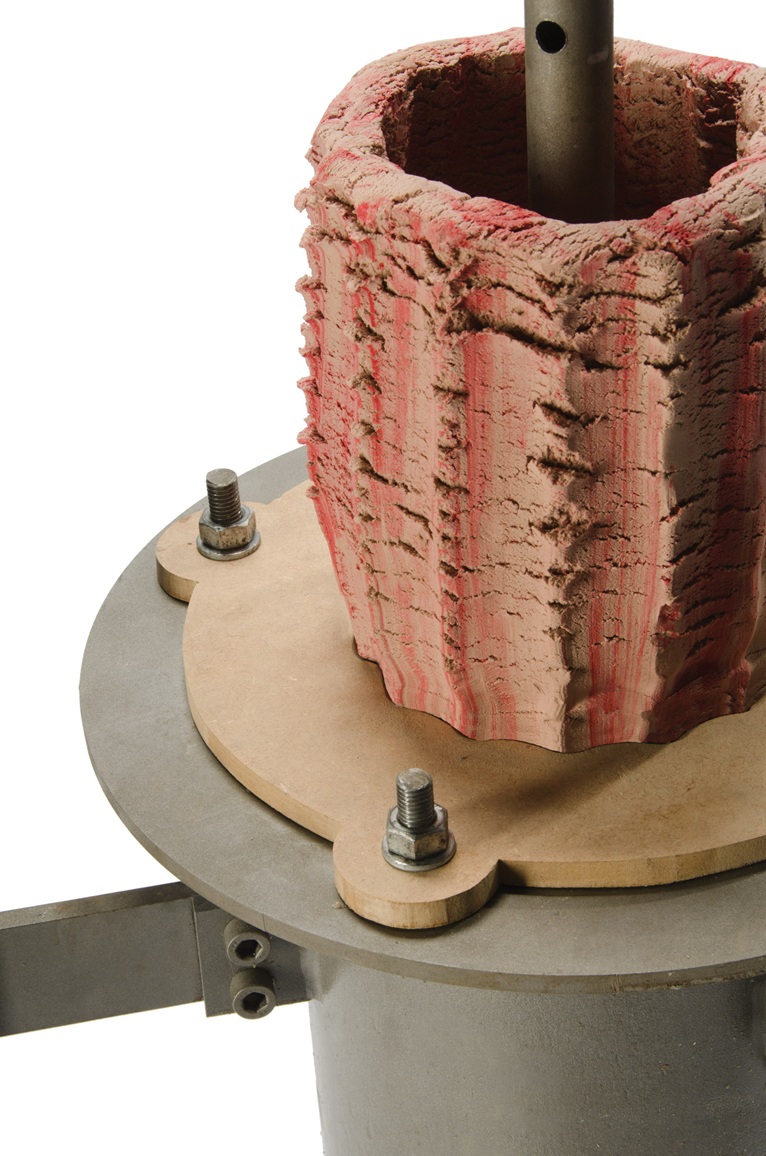

The items of the Pressed project are created with a self-developed press machine, and emphasize the meaning of human actions in creating objects. The choice in extrusion profiles and the way one moves the presser has a huge influence on the esthetical appearance of the final artifact.

Using the method of the Pressed project, humans and machines are working together in harmony; they need each other in order to create objects. Due to this distinctive craftsmanship, each unique object can be seen as a combination of mechanical production and handmade artifacts.

Vases of epoxy clay

During the manufacturing process the epoxy-clay is pressed through the extrusion profiles. As a result, machine and human behavior will not only define the products’ shape but also its tint. Combinations of extrusion profiles are endless; in this way there is an enormous variety of exclusive objects as outcome possible.

Moreover, it is a long-lasting material. The pressed Project facilitates a short and fast manufacturing process from semi-manufactured goods into a finalized product like for instance a vase.

Ceramic vases

The first Pressed vases where created with epoxy clay, while the new series is made out of ceramics. The same self-developed extrusion machine and production process is used. This is to explore materials’ characteristics and their behaviour when being molded through the extrusion profiles. The properties of both materials differ and become clear in the final product.

Photo © 2013 Studio Floris Wubben

7

7

comment